NanoAvionics has Fully Standardised All of its Nano- and Microsatellite Buses

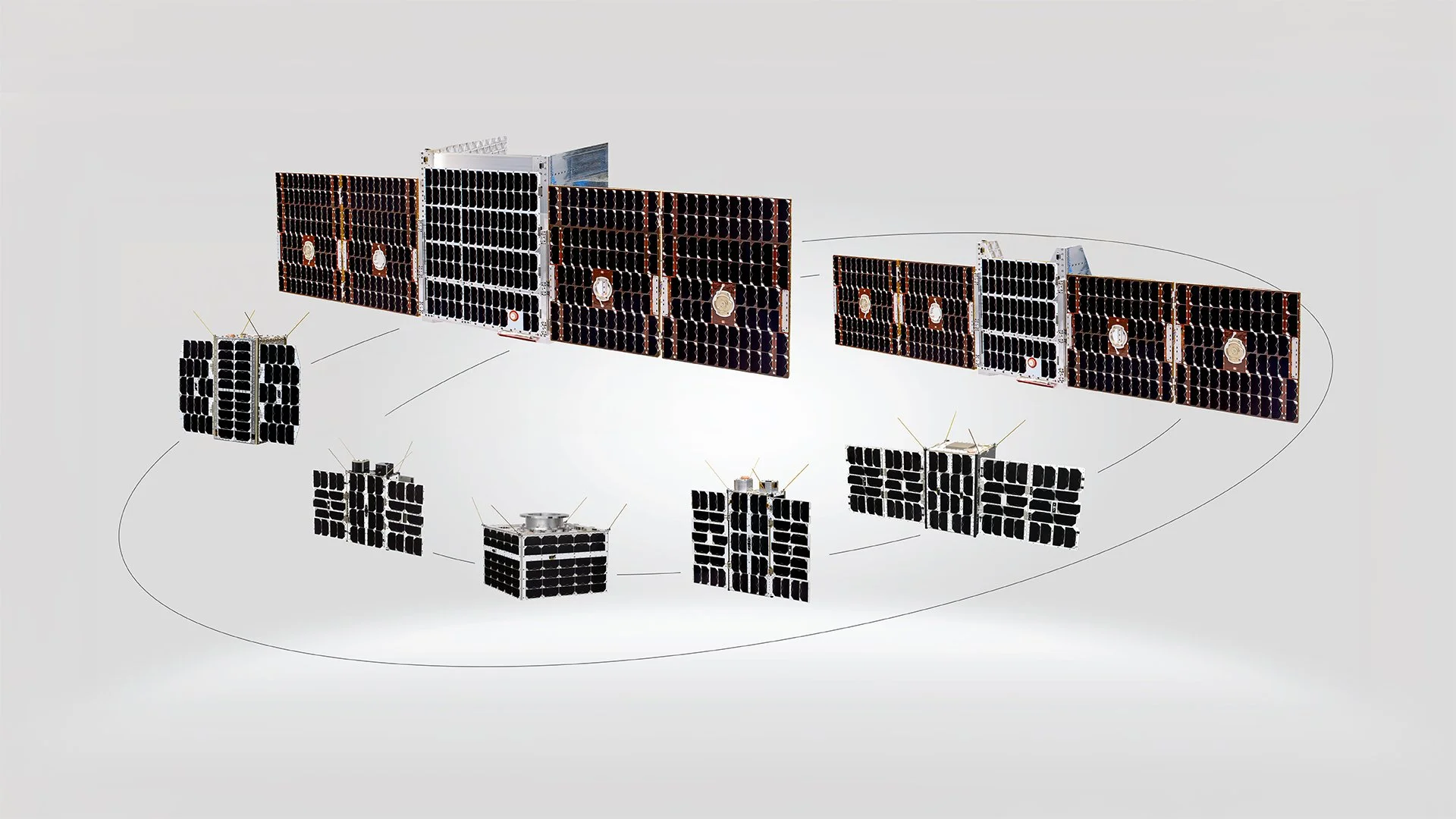

During a live broadcast, Kongsberg NanoAvionics (“NanoAvionics“) announced that it has now fully standardised all of its nano- and microsatellite buses. This standardisation significantly reduces lead times (starting at just four months for bus manufacturing), lowers costs, and improves reliability. Using standardised satellite architectures also enables faster and more cost-effectively missions launches than ever before. For space missions with non-standard requirements, NanoAvionics retains its customer specific customisation options.

In line with its holistic standardisation approach, the smallsat mission integrator and manufacturer has also revealed its new and simplified online configuration tool. Matching customers’ mission requirements, it has been setup to make it easier for them to order from NanoAvionics’s comprehensive range of satellite buses with transparency on lead times, prices and technical documentation.

Arnoldas Peciukevicius, director of product and mission development at NanoAvionics, said: “The standard buses are a culmination of a decade’s worth of mission experience and technological advancements. Reducing complexity and barriers to enter space at manufacturing and mission integration level further supports the growth of the NewSpace sector, with the expectation to accelerate it. This in turn enables startups and established firms alike to innovate and expand their space-based services. It also supports other customer segments such as governmental and research institutions”

According to NanoAvionics, the industry is now entering NewSpace 3.0, where the focus is on mission longevity, performance, reliability, and interoperability. It follows NewSpace 2.0, which saw a surge in private capital funding and commercial launches, surpassing governmental launches for the first time in history. It also brought about innovation in launch and satellite technology, new partnerships, and the rise of private satellite constellations.

NanoAvionics’s latest development is also a result of last year’s opening of its new MAIT (manufacturing, assembly, integration, and testing) facility in Vilnius, Lithuania. It doubled the company’s satellite production capability and further enabled the it to reduce lead times. It also puts the company in a perfect position to meet the demands for satellite constellations and larger satellites by commercial, civil, and governmental organisations.

Within the standardisation across its satellite buses, NanoAvionics offers three configurations (light, mid, and max) for each form factor to meet the diverse mission needs, industries and applications of its customers without extensive customisation.

“This productisation effort of our standardised satellite buses marks a significant leap forward in the company’s mission to streamline satellite deployment and enhance the accessibility of space technology,” Peciukevicius said.

“Together with our three configurations, our buses have a broad market appeal, from Earth observation to telecommunications and beyond. This reflects NanoAvionics’ commitment to facilitating a wider adoption of space technologies. The buses also incorporate the latest in aerospace technology, ensuring high performance, reliability, and high mission success rates.”